Production

Welding

MND Drilling & Services carries out the following welding operations

- 111 – Shielded metal arc welding

- 131 – Metal inert gas welding (MIG welding)

- 135 – Metal active gas welding (MAG welding)

- 141 – Tungsten inert gas welding (TIG welding)

- 311 – Oxy-fuel welding

Classes 1 through 11 of welded materials classified in accordance with CR ISO 15608

Wear-proof dressing of centralizers and drill pipes, using welding methods no. 111 and 135

Brazing (using a brass solder) of hard-metal inserts and hard-metal granules of varying sizes onto drilling tools:

- Front-end and concave mill reamers

- Reamer blades

- Section mill blade

- Centralizers

The abovementioned methods are utilized in the manufacture and repair of all our products.

Welding staff

Welding supervisors with European Welding Technologist (EWT) qualifications

Welders qualified in accordance with ČSN EN 287 – welding methods: 111, 131, 135, 141 and 311

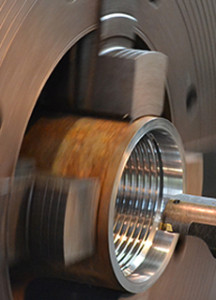

Drill Pipe Threads

- 2 3/8″ IF ( NC26 )

- 2 7/8″ IF ( NC31 )

- 3 1/2″ IF ( NC38 )

- 4 1/2″ IF ( NC50 )

Mills

A milling machine is a tool designed for wellbore cleaning and gauging (mostly utilized during workovers). It is comprised of a steel body with hard-metal granules in brass matrix soldered to its face and cylindrical body. The mill dimensions can range from 0.5 m and up in length and from 100 to 200 mm in diameter. It can be of a cylindrical, tapered or frontal design. The mill features an inner thread.

Pressure Vessels and Technological Systems

MND Drilling & Services provides manufacturing and repair services for oil and gas production and processing technological systems. Pressure vessels are designed and manufactured in compliance with Czech standards adapted to European guidelines.

- K – 01 Boiler for general liquid and gas heating applications

- K – 03 Boiler

- K – 3.4 MW Boiler

- DN 100 PN80 Filter/separator

- Gas separator – DRIP

- GASOLINE – GLYCOL separator

- DN 600 heat exchanger

- Vertical two-phase separator

- Continuous crude oil demulsifier

- PHP beam pump (5, 7, 10 ton)

Wellhead Installation Components

MND Drilling & Services offers a wide range of wellhead components compatible with API Standard casing and tubing specifications.

- Casing heads, including casing slips

- Tubing heads, tubing hangers

- Christmas trees

- Disc gate valve

- Centralizers

- Drill collars

- Working pressure range

- Up to 2,000 PSI / 13,9 MPa

- Up to 3,000 PSI / 20,7 MPa

- Up to 5,000 PSI / 34,5 MPa

- Up to 10,000 PSI / 69 Mpa